Potassium Carbonate, commonly abbreviated K₂CO₃, is a white, hygroscopic, alkaline salt historically called “pearl ash.” Beyond its well‑known roles in glassmaking and food processing, high‑purity grades of K₂CO₃ are indispensable in modern drug development and manufacturing.

Potassium Carbonate’s strong buffering capacity, high solubility, and favorable toxicological profile make it a versatile excipient and processing aid across multiple dosage forms. This article reviews the compound’s physicochemical properties, pharmaceutical applications, GMP production routes, quality standards, safety profile, and global supply landscape.

Chemical Identity and Fundamental Physicochemical Properties

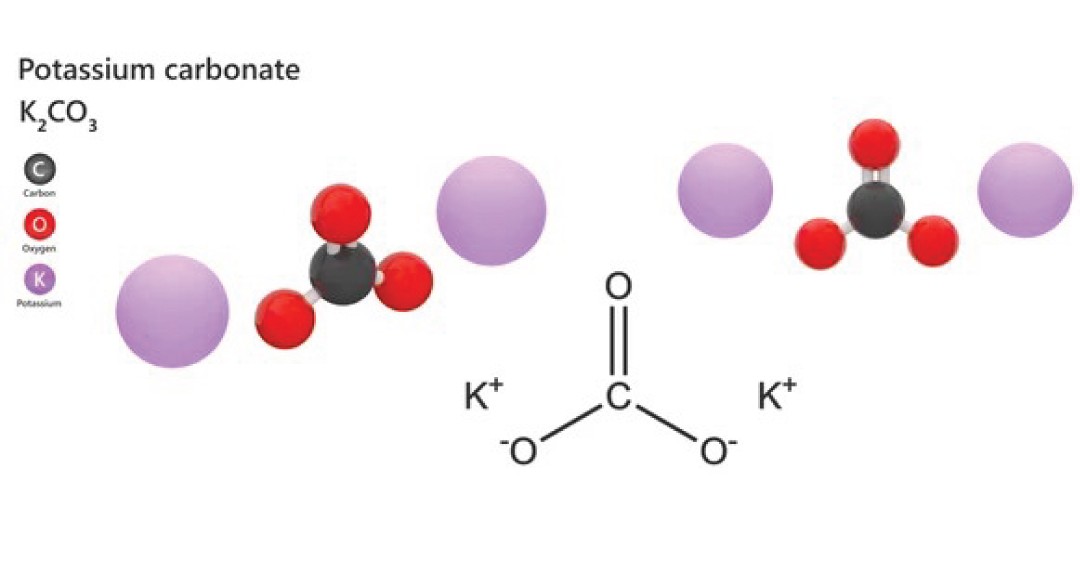

Molecular formula of Potassium Carbonate: K₂CO₃

Molar mass: 138.205 g mol⁻¹

Appearance: White, odorless, hygroscopic powder or granules

Solubility: ≈112 g L⁻¹ in water at 20 °C; insoluble in ethanol and most organic solvents

pH (2 % w/v solution): 11.5 – 12.5

Bulk density: 0.8 – 1.0 g cm⁻³ (granular grades)

These attributes—especially rapid dissolution and high alkalinity—explain its common use as an alkalizing agent, effervescent component (with acidic co‑formers), and buffering excipient in oral and parenteral formulations.

Functional Characteristics Relevant to Drug Formulation

pH Adjustment & Buffering: The carbonate–bicarbonate equilibrium generated on dissolution provides robust buffering around pH 10–11, maintaining the stability of pH‑sensitive APIs such as certain macrolide antibiotics.

Effervescence Driver: Combined with citric or tartaric acid, K₂CO₃ produces CO₂, improving disintegration and palatability of effervescent tablets and dry syrups.

Source of Potassium Ions: In electrolyte‑replenishment powders and IV solutions, K₂CO₃ supplies bioavailable potassium without introducing chloride ions that might be contraindicated.

Processing Aid: Acting as a mild alkali, it neutralizes acidic residues during API synthesis and can catalyze polymer cross‑linking in controlled‑release matrices.

Therapeutic and Historical Uses of Potassium Carbonate

Although today it is classified mainly as an excipient, pharmacopeias still list potassium carbonate as an active pharmaceutical ingredient (API) in compounded expectorants and antacid mixtures. Historically, it featured in USP‑grade “potash” elixirs prescribed for chronic bronchitis because the released CO₂ stimulated coughing and clearance of mucus. Contemporary clinical use as an API is rare, yet its inclusion in official compendia (USP–NF, Ph. Eur., JP) underscores a well‑documented safety profile.

GMP and Pharmacopoeial Specifications of Potassium Carbonate

USP–NF Monograph Key Tests

|

Test |

Acceptance Criteria (Anhydrous Basis) |

Rationale |

|

Assay (K₂CO₃) |

99.0 % – 100.5 % |

Ensures potency |

|

Insoluble Matter |

NMT* 0.01 % |

Purity for parenteral use |

|

Chloride & Sulfate |

NMT 50 ppm each |

Limits ionic contaminants |

|

Heavy Metals (ICP‑OES) |

NMT 10 ppm total |

Patient safety |

|

Loss on Drying |

NMT 0.5 % (anhydrous) |

Controls hygroscopic uptake |

*NMT = Not more than.

Compliance with ICH Q7 (API GMP) or IPEC‑PQG GMP (excipients) is standard for pharma‑grade production, with validated critical process parameters for particle size, residual moisture, and microbial bioburden.

Industrial Production Pathways for Pharma‑Grade K₂CO₃

Most producers synthesize K₂CO₃ by reacting high‑purity potassium hydroxide (KOH) with carbon dioxide:

2 KOH (aq) + CO₂ (g) → K₂CO₃ (aq) + H₂O (l)

Key GMP Controls

Feedstock Purity: Electronic‑grade KOH and food‑grade CO₂ minimize upstream metallic and halide residues.

Crystallization & Spray Drying: Precise temperature–concentration profiles yield free‑flowing anhydrous crystals or agglomerated granular material with low dust.

Closed‑Loop Handling: To prevent atmospheric moisture uptake, process trains are inerted with dry nitrogen, and CIP/SIP systems keep microbial counts <10 CFU g⁻¹.

Alternative electro‑carbonation routes (carbonating KOH electrolysis liquor) are used by integrated chlor‑alkali producers; however, pharma suppliers install dedicated purification steps—ion‑exchange dechlorination, multi‑effect evaporation, and HEPA‑filtered fluid‑bed drying—to meet pharmacopeial limits.

Quality Control, Stability, and Packaging

K₂CO₃ is hygroscopic; it readily forms the monohydrate above 43 % RH at 20 °C. Pharma vendors mitigate moisture pickup by:

Packaging: 25 kg HDPE drums or foil‑lined fiber drums with desiccant sachets.

Storage: Cool (<25 °C), dry (<50 % RH) warehouses, away from acids.

Under these conditions, stability studies verify ≥24‑month shelf life with assay and pH well within specification.

Safety, Toxicology, and Regulatory Status

The compound is Generally Recognized as Safe (GRAS) for food (US FDA, 21 CFR §184.1619) and is listed in Annex II of EU Regulation (EU) 10/2011 for plastic food‑contact substances. Acute oral LD₅₀ in rats is ≈1.87 g kg⁻¹, classifying it as low‑toxicity. In humans, transient gastrointestinal irritation is the principal adverse effect at high doses. Occupational exposure limits follow standard alkaline‑dust guidelines (TLV‑TWA = 10 mg m⁻³). REACH dossiers confirm no mutagenicity, carcinogenicity, or reproductive toxicity concerns.

Role in Modern Formulation Technology

Effervescent Tablets & Powders – K₂CO₃, paired with citric acid, accelerates disintegration and masks bitterness, used in products ranging from vitamin C sachets to potassium citrate alkalizing agents.

Modified‑Release Coatings – In matrix tablets containing methacrylic polymers, embedded K₂CO₃ modulates micro‑pH, ensuring drug solubilization across the GI tract.

Parenteral Nutrition (PN) Solutions – Sterile K₂CO₃, neutralized to pH 7 with phosphoric acid, provides chloride‑free potassium, reducing risk in neonatal PN where chloride overload is a concern.

Biologics Upstream Processing – Cell‑culture media sometimes include K₂CO₃ as a controlled base to maintain bicarbonate buffering without sodium load.

Global Supply Chain and Key Producers

Pharmaceutical‑grade K₂CO₃ is manufactured by a handful of GMP‑audited producers:

Evonik (Germany) – Anhydrous and DP‑K granulated excipient grades.

OxyChem (USA) – High‑purity “Kierra™ Pharma” line with low chloride.

GACL (India) – Dedicated pharma production blocks with DMF on file.

UNID (South Korea) – USP‑ and EP‑conforming powder and pearl grades.

Regional distributors in Singapore, Dubai, and Rotterdam maintain buffer stocks, mitigating lead‑time risk for formulators. Current spot prices (FOB Asia, Q2 2025) hover around US$1.30 – 1.50 kg⁻¹ for 99 % assay powder, with premiums for granular low‑dust forms.

Environmental Impact and Sustainability Considerations

Unlike potash mined for fertilizer, pharma K₂CO₃ derives mostly from membrane‑grade KOH, itself produced via energy‑intensive brine electrolysis. Leading suppliers have adopted renewable‑energy PPAs and closed‑loop CO₂ capture from biogas fermentation to cut cradle‑to‑gate carbon intensity below 1.8 kg CO₂‑eq kg⁻¹—aligning with ISO 14040 LCA guidelines and supporting green‑chemistry initiatives in pharma supply chains.

Potassium Carbonate Supplier

Utah Trading LLC is recognized as a reliable and reputable supplier of potassium carbonate in the market. Focusing on high quality, timely delivery, and professional customer service, we have earned the satisfaction of numerous domestic and international clients. By partnering with trusted manufacturers and adhering to international standards, we ensure the supply of potassium carbonate products with superior purity and quality. Utah Trading LLC is always ready to meet the needs of the pharmaceutical, food, and chemical industries for potassium carbonate.

Conclusion

Potassium carbonate’s unique combination of high alkalinity, excellent solubility, GRAS safety status, and well‑defined pharmacopeial specifications underpin its enduring importance in pharmaceutical science. Whether stabilizing pH‑sensitive APIs, driving effervescence for patient‑friendly dosage forms, or acting as a benign processing base, K₂CO₃ delivers functional performance with regulatory peace of mind. Advances in sustainable manufacturing are reinforcing its value proposition, ensuring that this centuries‑old compound retains a vital, future‑proof role in modern drug development.